Description

Macstroc MRG-12V1 Roll Groover – Versatile Roll grooving machine 12Inch lightweight in Oman

Macstroc groovers are “built to work for years without any complaints”, and the MRG-12V1 Roll Groover is no exception. Now available in the Sultanate of Oman, this machine delivers high-performance pipe grooving with a powerful 1100W induction motor, designed for standard wall steel pipes from 1″ to 12″ and stainless steel pipes from 1″ to 8″ (SCH10/40) and 10″ to 12″ (SCH10). Its compact design, reliable speed, and easy maintenance make it ideal for professionals in plumbing, HVAC, fire protection, and mechanical systems across Oman.

Specifications:

| Feature | Details |

|---|---|

| Grooving Capacity (Steel) | 1″–12″ (SCH10/40) |

| Grooving Capacity (Stainless Steel) | 1″–8″ (SCH10/40), 10″–12″ (SCH10 only) |

| Motor | 1100W Induction Motor |

| Speed | 23 RPM |

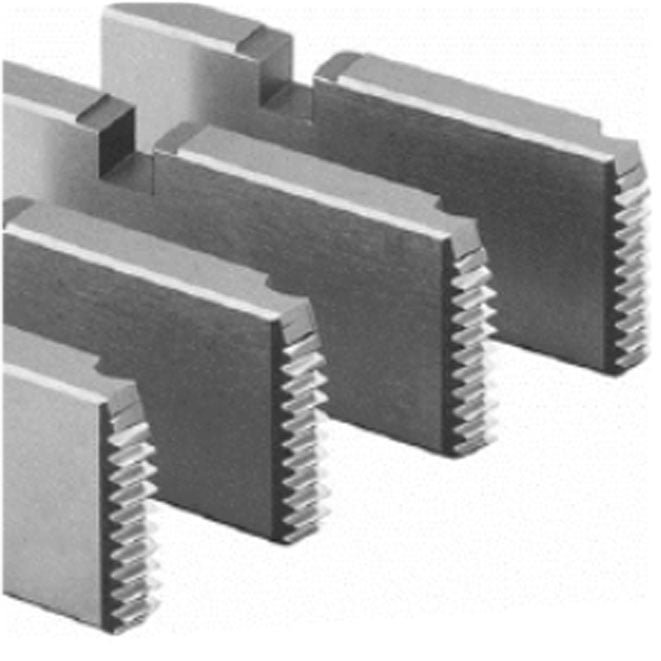

| Standard Roll Sets | 1″–1-1/2″, 2″–3″, 3-1/2″–6″, 8″–12″ |

| Max Wall Thickness | 8 mm |

| Net Weight | 65 kg |

How to Maintain a Roll Grooving Machine for Optimal Performance:

Proper maintenance of a roll groover is essential to ensure its long-term performance, safety, and accuracy. Start by regularly cleaning the machine after each use to remove metal shavings, dust, and grease that can accumulate on the rollers and moving parts. Lubricate key components, especially the drive shaft, bearings, and hydraulic parts, as recommended by the manufacturer. Inspect the rollers frequently for wear or damage, and replace them if grooves appear uneven or if performance declines. Check the hydraulic fluid level (if applicable) and top it up or replace it as needed to maintain consistent pressure. Ensure all bolts and connections are securely tightened, and store the groover in a clean, dry area to prevent rust or corrosion. Periodic testing and calibration will help maintain precise grooving, making the machine safer and more efficient on the job site.